A French company specialized in the production of fresh, unprocessed vegetables has been using ABIOTEC’s UV systems for the disinfection of its process water for the past ten years. A look back at their experience.

In 2014, a French company specializing in the production and sale of fresh, unprocessed vegetables chose a process water disinfection solution using Abiotec’s UV technology. The system was installed on the wastewater stream from the washing process, after sedimentation and filtration. The treated water is then reused for a second washing cycle. This process achieves a water savings of approximately 80%.

“We chose this solution partly because the network couldn’t provide enough flow, and also for cost reasons. UV systems are robust, and they are neither expensive nor demanding to maintain. We only need to replace the lamps once a year to remain compliant. After that, we’re worry-free” says the plant’s technical manager.

Compensating for Fluctuations in Borehole Water Quality.

At certain wavelengths, UV technology destroys microorganisms without altering the chemical composition of the water. To take advantage of this benefit, the company recently invested—once again with Abiotec—in a second UV system. The unit is directly connected to the borehole, where water quality could fluctuate. It ensures food-grade water quality for the final rinsing of vegetables.

“Thanks to UV systems, we are not dependent on the water supplier. And above all, we obtain chlorine-free water, an essential quality for our use,” says the technical manager.

UV disinfection does not use any chemicals and does not alter the physical chemistry of the water. This criterion is crucial for preserving the integrity of vegetables, even after purchase.

“Without this treatment, products would deteriorate more quickly due to bacteria and high temperatures. Thanks to UV rays, their preservation is improved, and the consumer benefits from a healthier and more sustainable product,” he adds.

Maintenance is reduced thanks to daily manual cleaning and rigorous performance monitoring.

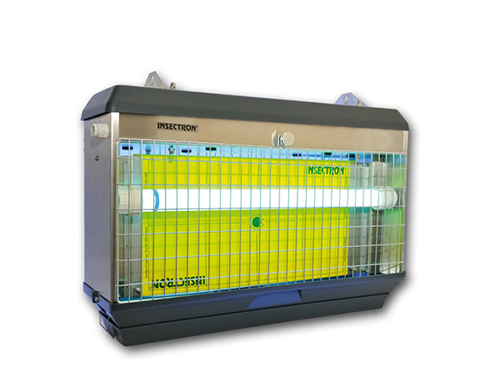

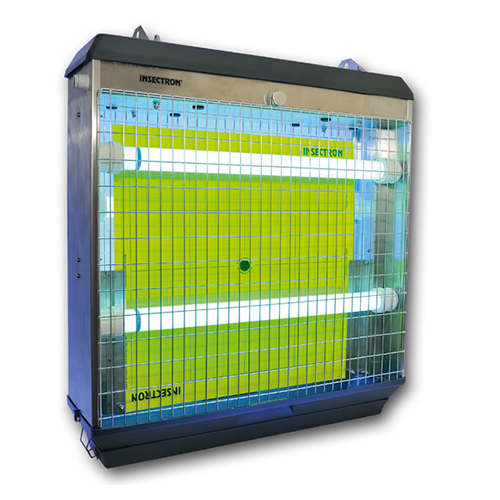

An integrated controller provides alarm reporting and displays the UV dose in J/m². The existing UV systems, the BLE4.250 with four lamps for drinking water and the BLE6.250 with six lamps for process water, are available with hydraulic connections that meet the plant’s standard. They feature an openable and self-draining 316L stainless steel chamber.

Satisfied with these solutions, the company has duplicated the process in another of its plants.

—

Article by Stéphanie PERRAUT